Speeds and Feeds Calculator Good Calculators

The Speeds and Feeds Calculator may be employed for calculations of estimated speeds and feeds (RPM and IPM) values on the basis of the parameters you .

WhatsApp)

WhatsApp)

The Speeds and Feeds Calculator may be employed for calculations of estimated speeds and feeds (RPM and IPM) values on the basis of the parameters you .

Formula to Calculate 420ma from Percentage Calculate the equivalent 420 mA loop current value for any given percentage of signal. We need field transmitter span, lower range value and upper range value.

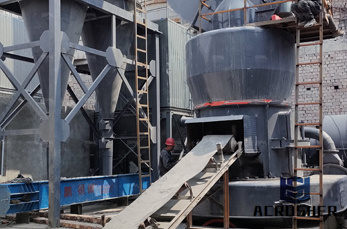

that of a vertical roller mill (VRM) carrying out the same oper ations by a factor of between and 2, depending on the degree of optimisation of the ball mill. Fig. 1 illustrates this connexion, as well as showing the increasing energy benefit that can be obtained with a vertical roller mill as the specific Blaine surface area rises.

Performances of vertical roller mill and closed ball mill circuit in cement grind ing application (C EM I R) were compare d in terms of energy consumption and

how can we calculate the rpm of ball mill. Ball Mill Critical Speed 911 Metallurgist. Mar 17 2017 The critical speed of a rotating mill is the RPM at which a grinding medium You ll find a good online tool for ball mill critical speed calculation >Price ball mill calculation for cement plant MC World C. ball mill calculation for cement plant.

VRM HEAT MASS BALANCES SHEET. Dear all. i need to know what the method for calculate heat and mass balance of vertical roller mill with capacity 400TPH(.5%MOISURE) and kiln capacity 4500TPD,six stage? Reply. Know the answer to this question? Join the community and register for a free guest account to post a reply.

シーユーアイ・ジャパン 〒 2118 ビル8F Tel: Fax:

Standard methods to calculate paper and board characteristics require the use of the International System of Units (SI or SI metric units). Calculating paper. Details of SI are provided in the ISO Standards 31:1981 and 1000:1981. Some quantities can be expressed in different SI units. Such variations can lead to confusion in reporting test ...

To calculate your tax based on your mill rate, divide your assessed value by 1,000 and multiply the result by your mill rate. In turn, a home with a market value of 500,000, and consequently a 350,000 assessed value and a mill rate of 50, would pay 17,500 in annual property taxes.

Processing... ... ...

Sep 01, 2017· The wet film thickness target (or range) can be calculated. The equations for calculating the WFT, both with and without thinner addition, are shown. The dry film thickness range (per coat) is extracted from the specification or the coating manufacturer''s PDS (whichever is the governing document) and the volume solids content is listed on the ...

ppm to percent converter How to convert percent to ppm. 1% = 10000ppm. So. x (ppm) = 10000 ⋅ x (%). Example: find how many ppm are in %. x (ppm) = 10000 ⋅ % = 17000ppm. Percent to ppm conversion table

Theoretical Metal Weight Calculator. Below is the calculator for you to calculate the weight of various metals. What you need to do is calculate the sectional area and find the metal density. For the metal density, you can also refer to: Density Table of Metals (Iron, Steel, Brass, Aluminum) and Alloys;

Apr 29, 2017· 1 Formulas for Calculating Sugar Industry Daily Manufacturing Report (DMR) With Simple Online Calculator. Fundamental formula : Sugar balance : Mill Extraction (M E). Fibre % Bagasse : Added water%fiber; Reduced Mill extraction : Noel Deer and Mittal Clarification Factor: Theoretical Final Molasses % cane :

mill working volume was l. A screen cartridge with a screen size of mm was used to separate the beads and slurry at the outlet of the mill. All tests were performed with a grinding media filling grade of 80 volume% (mill working volume). The stirrer tip speed was set at 6 m/s and 10 m/s. Milling product and formulation

Vertical mill calculations Symbols Power consumption Grinding pressure Mill internals Nozzle ring Dam ring Heat balances, Example Layout Alternatives There are two basic layouts of the VRM system; product collection in cyclone(s) or product collection in filter.

ROLLER MILL. Used in cement industry Vertical Mills used for Pregrinding of clinker (lumps to coarse powder) Finish grinding (lumps to powder) of Coal/Petcoke for kiln Raw materials for kiln Cement, OPC or mixed Slag, pure or mixed VRM Functions Vertical Roller Mill (VRM) Details feed gate (air lock) mill casing water injection dam ring louvre ring nozzle of material scraper mill .

The maximum power draw in ball mill is when ball bed is 3540 % by volume in whole empty mill volume. Considering that ball bed has a porosity of 40 %, the actual ball volume is considered to be ...

Calculator Use. This online conversion calculator will convert among different units of weight or mass. For more specific calculations use avoirdupois unit conversions and troy unit conversions. How to Convert Units of Weight. Conversions are performed by using a conversion factor.

Jan 01, 2020· Massachusetts voters passed the ballot initiative in 1980. The law limits the amount of property taxes a city or town can raise in two ways: The amount raised in property taxes can never be more than 2 ½ percent of the full cash value of all taxable .

Mass/Volume Flow Determination. The relationship between the mass (M) and the volume flow (Q rates in a given stream is defined as: = the pulp density (solids and water) in lbs/ft 3 X = solids concentration in % by weight; Volumetric flow rate can be measured by flow meters, PQ curve relationships for pumps or directly measured.

A 420mA temperature transmitter with a range of 0 tot 100 degrees Celsius measures a temperature of 20 degrees. Then a current of 7,2 mA will flow in the loop. The current corresponding to a measured physical value is converted with the 420mA scaling calculator .

The Speeds and Feeds Calculator may be employed for calculations of estimated speeds and feeds (RPM and IPM) values on the basis of the parameters you have currently set based on your tools and stock material

Aug 08, 2013· Vertical roller mill Feed size: f (Roller Ø ) Material bed Feed material Max Particle size in feed: 58 % of roller diameter Grinding force = Roller weight + (pressure) Force Table moves with drive Roller rolls freely with table 8/7/2013 5.

WhatsApp)

WhatsApp)