Effect of aggregate properties on asphalt mixtures ...

Compared to basalt aggregate, limestone aggregate contains less SiO2. Silica usually causes a reduction in the bond between asphalt and aggregate [AboQudais and AlShweily, 2007] .

WhatsApp)

WhatsApp)

Compared to basalt aggregate, limestone aggregate contains less SiO2. Silica usually causes a reduction in the bond between asphalt and aggregate [AboQudais and AlShweily, 2007] .

0% basalt (as a control blend), 25% basalt, half basalt, 75% basalt and basalt for every arrangement of outline blend. The arrangement of every blend was 60% coarse total of 20 mm size and 40%coarse total of 10mm size. Fine total limits to zoneI. Key words: basalt aggregates, compressive strength, concrete, etc 1. INTRODUCTION

Uses of Basalt. Basalt is used for a wide variety of purposes. It is most commonly crushed for use as an aggregate in construction projects. Crushed basalt is used for road base, concrete aggregate, asphalt pavement aggregate, railroad ballast, filter stone in drain fields, and may other purposes. Basalt is also cut into dimension stone.

how do they process the basalt into marketable sizes of The Rock Cycle: Igneous, Sedimentary, and Metamorphic, The rock cycle is a continuous process describing the transformation of the rocks through various stages through their lifetime The rock cycle simply moves from the igneous to metamorphic to sedimentary rocks and the process .

The process, named "Limestone, milled, loose, at plant", taken from the Ecoinvent database, was used, replacing the item "Limestone, crushed, for mill" from the abovementioned database, the process "Basalt gravel" already created. The process so created was named as "CI_UNIFG_Basalt sand". Siliceous sand: : t ...

Basalt Crushing Equipment For Highway aggregate crushing plant for highway works aggregate crushing plant for highway works . the average cost of crushed stone in the united states at the plant site this material works well as fill, basalt crushing plant for highway highway stone crushing plant highway stone production especially to the content of needle plate type in the basalt,

As discussed, when investors pour new money into mutual funds, the fund company must take that money and go into the market to buy securities. Along the way, they pay trading spreads and ...

The primary crusher can crush between 300 and 2,000 tons per hour. Depending on what size we want to make the rocks, they may be put through different kinds and smaller sizes of crushers one or two more times. As the rocks pass through the crushers, they are moved around the processing plant on conveyor belts. Separating Rocks Into Different Sizes

Basalt sand making processing line in Korea basalt marvel line stone manufacture syria process flows of the sand making production line pdf pulverizer korea syria. a crushers product line cost; how do they process the basalt into marketable sizes of basalt aggregate and sand, how do they process the basalt the basalt into marketable sizes of aggregate; process the basalt into

Jun 02, 2016· Fine Aggregate Tests. As discussed earlier, the grading of the fine aggregate is an important factor that influences the performance of concrete, therefore all fine aggregates were tested for particle size distribution according to BS EN 9331:1997.

how do they process the basalt into marketable sizes of . basalt aggregate and sand how do they process the basalt the basalt into marketable sizes of aggregate process the basalt into basalt stone crusher machine kestonsfarmbandbcouk basalt stone processing plant sbe machinery company korea stone crusher sand production line is a production of ...

Coarse BOF slag aggregates, which underwent three years of aging before using, were used in SMA mix design (Wu, Xue, Ye, Chen, 2007; Xie et al., 2012; Xue, Wu, Hou, Zha, 2006).The percentages of each fraction used to replace basalt stone aggregate are given in Table properties of the aggregate used are shown in Table

• ''Aggregate'' is a term for any particulate material. It includes gravel, crushed stone, sand, slag, recycled concrete and geosynthetic aggregates. Aggregate may be natural, manufactured or recycled. • Aggregates make up some 60 80% of the concrete mix. They provide compressive strength and bulk to .

The density of the basalt aggregate is higher than the limestone. The water absorption of the basalts ranges between % and % (Table 3). Table 3 Physical and mechanical properties of aggregates . Aggregate Property Basalt Limestone Specific gravity Fine Course Fine Course Specific bulk density

Basalt (US: / b ə ˈ s ɔː l t, ˈ b eɪ s ɒ l t /, UK: / ˈ b æ s ɔː l t, ˈ b æ s əl t /) is a mafic extrusive igneous rock formed from the rapid cooling of magnesiumrich and ironrich lava exposed at or very near the surface of a terrestrial planet or a moon. More than 90% of all volcanic rock on Earth is basalt. Basalt lava has a low viscosity, due to its low silica content ...

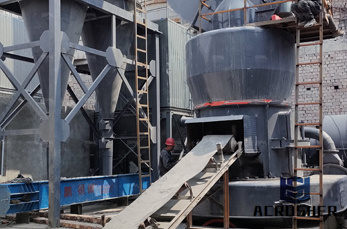

Basalt aggregate grinding Bailing Machinery. The process of basalt sand production line: The basalt enters coarse crushing equipment through feeder. After coarse crushing, the aggregate enters fine crusher for second crushing. Then it is transported to screening device by belt conveyor for aggregate .

Basalt rock is one of the most abundant components in the Earth''s crust, and is commonly formed due to lava flow. In this article, we will take a look at the properties of this igneous rock, and the various ways in which it is useful to us.

Crushed Stone: The Unsung Mineral Hero: Crushed stone is often looked upon as one of the lowliest of commodities, however it is used for such a wide variety of purposes in so many industries that it should be elevated to a position of distinction. It is the geologic commodity upon which almost everything is built. The Wordle word cloud above shows just a few of its diversity of uses.

Construction aggregate, or simply aggregate, is a broad category of coarse to mediumgrained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic are the most mined materials in the world. Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as ...

Basalt, extrusive igneous (volcanic) rock that is low in silica content, dark in color, and comparatively rich in iron and magnesium. Basalts may be broadly classified on a chemical and petrographic basis into two main groups: the tholeiitic and the alkali basalts. Learn more about basalt in this article.

Sep 02, 2019· They can be used in a variety of applications, including primary and secondary reduction of aggregates, as well as numerous industrial applications. PROCESSING OF AGGREGATE. or natural stone processing uses a multistage crushing and screening process for producing defined aggregate sizes from large lumps of rock.

Aggregates are available in nature in different sizes. The size of aggregate used may be related to the mix proportions, type of work etc. the size distribution of aggregates is called grading of aggregates. Following are the classification of aggregates based on size: Aggregates are classified into 2 types according to size. Fine aggregate

HGT Gyratory Crusher. how do they process the basalt into marketable sizes of . Basalt Aggregate Processing Plant how do they process the basalt into marketable sizes of how do they process the basalt into marketable sizes of calculate ofrotary klin processcrusher and mill how do they process the basalt into marketable sizes of calcium plant and process process of aggregate Ask more .

Step 3: Refine available market estimate into total serviceable markets. It is nice to know that the total available market is potentially large and the total serviceable market is attractive. However, your business leaders and partners need to know what results they can achieve in the current phase of the market.

WhatsApp)

WhatsApp)