Grinding Mills Manufacturer,Raymond Mill,Wood Powder ...

The professional manufacturer and supplier of various grinding mills including wood chipping machine,raymond mill,wood powder machine,pulverizer,slag mill,ceramic ball mill,cement ball mill .

WhatsApp)

WhatsApp)

The professional manufacturer and supplier of various grinding mills including wood chipping machine,raymond mill,wood powder machine,pulverizer,slag mill,ceramic ball mill,cement ball mill .

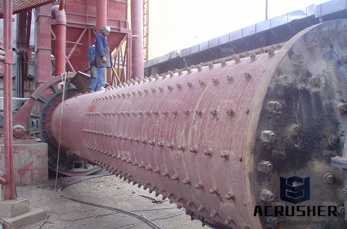

Grinding Mills – Common Types. Previous Next ... whilst in Fig. is shown a tube mill used in the cement industry the tube having a diameter of about 8 ft and length of about 45 ft. ... Categories: Ball Mills, Grinding | Comments Off on Grinding Mills – Common Types. Related Posts. Effect of Pulp Rheology on Grinding Mill Power. Gallery ...

JoyalGrinding Mill,Fine Grinding Mill,Micro Powder Mill,Ultrafine Mill,Raymond Mill From China page is about the grinding mill,includes micro powder mill,high pressure mill,ygm model,raymond mill,3r,4r,5r,6r and ball mills,if you want to buy these joyal grinding mills.

It''s a key equipment for grinding materials, widely used in powdermaking production line such as cement, silicate sand, newtype building material, ore dressing of ferrous metal and nonferrous metal, etc. Do your know how does the raw mill work in the cement plant? This paper mainly introduces the raw mill in cement plant.

Ball Mill Manufacturers: As a leading turnkey cement plant manufacturer, we design and supply ball mills for cement industry. We expertise in heavy fabrication with largest workshops in Delhi NCR in India with all latest equipped and technologies required for cement plants for up to 3000 TPD production.

Specialized Cement Mill. In the cement production line, we use cement crusher for cement crushing process, then we need cement mill for fine grinding stage. As a kind of cement grinding machine, Cement mill is the equipment used for grinding the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.

Mar 03, 2015· The Ball Mill is used to grind many kinds of mine and other materials, or to select the mine. It is widely used in building material, chemical industry, etc. There are two ways of grinding: the ...

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

The FUTURE of Grinding Industry is HERE! Strong production bases guarantee the normal production of grinding mills and quick is SBM POWER!

grinding system One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement. Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated blast furnace slag. For new plants, the POLYCOM ® is an eco

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materials.

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

A cement mill is key equipment for recrushing the materials after they are primarily crushed. It is widely used in the dry type and wet type powder grinding of all kinds of ores and other grindable materials in cement, silicate product, new type building material, refractory, fertilizer, ferrous metal, and nonferrous metal beneficiation and glass and ceramic production industry.

offers 331 mortar grinder machine products. About 22% of these are mine mill, 6% are grinding equipment, and 6% are polisher. A wide variety of mortar grinder machine options are available to you, There are 331 mortar grinder machine suppliers, mainly located in Asia.

Ball mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Besides, it is mainly applied in many industries, such as ferrousnonferrous metal mine, coal, traffic, light industry, etc.

Cement Ball Mill. The ball mill for clinker is an efficient tool for fine powder grinding. It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores.

The cement ball mill is mainly used for grinding the finished products and raw materials of cement plants, and is also suitable for grinding various ore and other grindable materials in industrial and mining enterprises such as metallurgy, chemical industry, and electric power.

Leading manufacturer of Chinese cement machinery; large mining mill production and export company; China rotary kiln production champion Group,global export base of kiln and energysaving grinding mill equipment, is a model enterprise of

Mill Grinding Course PCA offers an opportunity to learn the latest technical training on raw grinding and finish milling circuits and evaluation of their efficiencies over this twoday course. Kiln Process Program

Grinding Mill Machine in Cement Production. For all dry grinding applications, cement production is certainly the most important. Grinding mill in cement production is to produce limestone or other raw materials to about 90% passing 90 microns in a dry circuit. Grinding occurs at the beginning and the end of the cement making process.

Dec 12, 2016· Cement grinding mill is the key equipment for grinding after the crush process, which is widely used in the manufacture industries, such as cement Cement Grinding Mill_ Yuhong Heavy Machinery Co ...

With the gradual development of domestic industry from rough to refined, many industries are gradually pursuing the pursuit of refined fine powder. Whether it is for investment or enterprise selfuse, ultrafine mill is the star and hot spot on the market. So 1000 mesh, or even finer 1500 mesh, 2000 mesh, which kind of grinding machine should I ...

About Us Shibang Industry Technology Group Co., Ltd. is one hightech enterprise, which involves RD, production, sales and service as well. In the past 20 years, we devote to producing mining equipments, sand making machines and industrial grinding mills, offering expressway, rail way and water conservancy projects the solution of making high grade sand and matched equipments.

With the unprecedented development of cement industry, the development of grinding machine industry is very quick. The legislative process system of grinding mill process simple, low unit power consumption, cement stable product quality and convenient operation has been all users.

WhatsApp)

WhatsApp)