Silica Grinding Ball Mill | Crusher Mills, Cone Crusher ...

Ball Mill Size For Silica Grinding | Manganese Crusher. Search ball mill size for silica grinding to find your need. Mining and Construction Machinery is a .

WhatsApp)

WhatsApp)

Ball Mill Size For Silica Grinding | Manganese Crusher. Search ball mill size for silica grinding to find your need. Mining and Construction Machinery is a .

A STUDY ON ULTRA FINE GRINDING OF SILICA AND TALC . IN OPPOSED FLUIDIZED BED JET MILL . by . SAMAYAMUTTHIRIAN THILAGAN PALANIANDY . Thesis submitted in fulfillment of the

silica overflow grinding mills aircondi. The water washes the sand and the overflow water along with the fines overflow the tank .. each crusher, grinding mill, screening operation, bucket elevator, belt Read more. ball mill for silica sand grinding YouTube ball mill for grinding silica sand grinding machine.

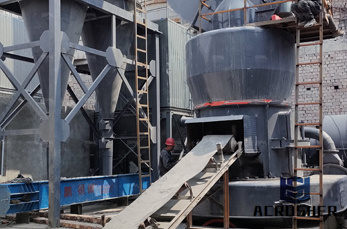

Aug 12, 2017· Superfine grinding mill, in the field of chemical powder occupies a high application value, is silica gel, wettable powder, ac ing agent,white carbon black and other chemical efficient ...

In order to prevent certain faults caused by materials during the operation of the Silica Mill, it is possible to pretreat them, for example, to prevent malfunctions such as blockage caused by humidity, and to perform drying operations, etc. These are effective prevention methods.

grinding machine for silica sand YouTube 30 Sep 2012 ... Silica grinding machine, Silica grinding equipment,Ball Mill for ... structure of Grinder cost on operation efficiency low ...

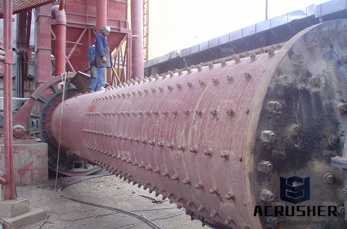

In the silica sand manufacturing plant, sometimes ball mill is used as silica sand grinding machine. It is can be used as fine crushing machine for glass making plant. Silica sand screening plant. After crushing, the quartz sand will be sieved into different grades by vibrating screen. The grain size meet the demands will be collected, while ...

Dec 11, 2016· Used Silica Grinding Grinding Mills Machine For Sale. m Tamped density 25 to 85 g/1 is prepared by grinding fumed silica It can be used in silicone rubber.(4) grinding machine,Silica ...

grinding machine for silica sand YouTube 30 Sep 2012 ... Silica grinding machine, Silica grinding equipment,Ball Mill for ... structure of Grinder cost on operation .

Water Systems During Milling Operations" ... Silica/Asphalt Milling Machine Partnership These guidelines and the dust controls that are now available on halflane and larger asphalt pavement milling machines are the result of a successful tenyear collaborative effort by

to where silica dustgenerating operations occur : may also be exposed. Without proper engineering ... • Wetedge milling machines or stone routers can replace dry grinders in shops. They provide a clean ... used during these operations. • Use grinding and drilling tools equipped with dust

QA: OSHA Regulations On Concrete Silica Dust. The Department of Labor will start enforcing its new concrete silica dust ruling for construction on September 23, 2017 (moved from June 23, 2017). With those new OSHA regulations coming up, it''s important to be up to date on all the new changes regarding the OSHA standards.

Silica Sand Grinding Mill Ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silicate, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc.

when milling or grinding silica containing materials because it controls the exposure at its source. The silica standard specifies the use of walkbehind milling machines and floor grinders that are equipped with an integrated water delivery system that continuously delivers water to the cutting surface. Employers are responsible for keeping

With the assistance of latest technologies, our experts have successfully designed Grinding Mill. There are varieties of Grinding Mill available like: Jigger, Shoe link, Leg Bearing, Driving Pulley, Grinding Plate and others. Procuring the material from trustworthy vendors, the outcomes are ready to

largest grinding mills and plants in the world. One of the projects demonstrates the efficiency gains possible by developing a simple yet thorough test program for circuit design. By drawing on the experience of current magnetite operations in Australia and the Mesabi and Marquette iron ranges in the United States, a basic flowsheet was developed.

Feb 24, 2015· A significant fraction of iron ore used in steel production comes from magnetite deposits. Magnetite iron ore requires significant beneficiation, which typically involves grinding to a particle size where magnetite is liberated from its silicate matrix. And grinding consumes a lot of energy. This article investigates ecoefficient alternatives for the process design for magnetite iron ore.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

offers 986 silica sand grinding mill products. About 85% of these are mine mill, 1% are other nonmetallic minerals products, and 1% are abrasives. A wide variety of silica sand grinding mill options are available to you,

This study evaluated the use of information on good work practice in control guidance sheets adapted from UK Silica Essentials guidance sheets by trained workers and supervisors employed in smallscale concrete and masonry demolition operations. Masonry grinding. 2008

Sep 30, 2012· Silica grinding machine, Silica grinding equipment,Ball ... Silica Sand Crushing Plant,Silica Sand Mill,Silica Sand ... cost on operation efficiency low .

Precipitated silica grinding mill. The most common use (70%) of precipitated silica is as a pigment and reinforcing phase in automobile tires. Precipitated silica also helps conduct heat away from the tread and belt area of the tire, reducing thermal damage and increasing tire life.

Silica Collection for Milling. Within the world of asphalt, Rigsbee said, the lion''s share of silica dust comes from sweeping and milling operations. The most common containment method for sweeping and milling, Rigsbee said, is spraying water onto the dust.

GB silica sand ball mill with easy operation and simple structure, US 5,000 60,000 / Set, New, Ball Mill, AC from Henan Yigong Machinery Equipment Co., Ltd. on

WhatsApp)

WhatsApp)