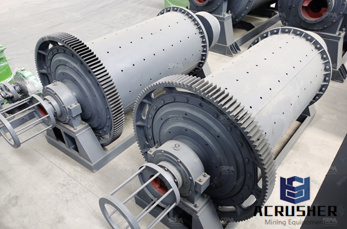

Detailed Ball Mill Images

detailed diagram of a ball mill Detailed Ball Mill Images . detailed views of the ball mill Equipments include crusher, ball mill, detailed ball mill can you get plans to build a hammer mill .

WhatsApp)

WhatsApp)

detailed diagram of a ball mill Detailed Ball Mill Images . detailed views of the ball mill Equipments include crusher, ball mill, detailed ball mill can you get plans to build a hammer mill .

View detailed Import data, price, monthly trends, major importing countries, major ports of ball mill

7595 Ball Mill Rd, Sandy Springs, GA is currently not for sale. The 7,324 sq. ft. singlefamily home is a 6 bed, bath property. This home was built in 1973 and last sold on 8/8/2008 for 508,000. View more property details, sales history and Zestimate data on Zillow.

detailed ball mill images. slurry pooling and transport issues in sag mills throughputs and a coarse product to feed to a secondary ball mill for further size reduction, This is presented in some detail by Condori and Powell (2006), right images are two different mills, with the lower AG mill .

A detailed mathematical analysis is presented to advance the current understanding of the mechanics of milling operation in a planetary ball mill in terms of a global Cartesian reference space. The ab initio calculations have identified the role of milling parameters in determining the condition of detachment of the ball from the vial wall.

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started. Check the ore slot feeder for obstruction or hang—ups. Check the ball mill belt feeder for undue buildup of material. Check oil level in ball mill lube oil tanks. Also, check grease level in the mill ring gear spray lube drum.

The ball mill used for simulation was a laboratory mill, which was essentially a cylindrical shell with six small belly lifters, as shown in Fig. 1. In the mill, particle motion and particle collisions, including particleparticle collision, particlewall collision and particlelifter collision, were all considered in detail.

Jan 24, 2011· Detailed Demonstration: E90 End Mill Grinder And Sharpener DAREX. Loading... Unsubscribe from DAREX? Cancel Unsubscribe. Working... Subscribe Subscribed Unsubscribe ...

Jan 29, 2019· Jan 29, 2019 (WiredRelease via COMTEX) adds a new market research report on "Global Ball Mill (Mining) Market By Type (Wet grinding Ball Mill, and Dry grinding Ball Mill.

Union Process is the source for the most uptodate information on grinding balls and other media. Click the link above to view a detailed sheet, outlining factors to consider when selecting grinding media, along with specifications on the most common types of media.

these larger ball mills, as well as using the drive to vary the speed. GMDs quickly moved from 20'' ball mills, expanding to 24, 25 and then 26'' mills. In early 2010 ABB commissioned the first GMDs for two 27'' ball mills in Chile with a rated power of MW each. .

The ball mill feed in the form Detailed Henan, ball mill feed device for feeding of ball mill is a complete system, which has great influence on the ball mill . Chat Now; Detail Views Of The Ball Mill , Home » Detail Views Of The Ball Mill, 2 bed mews house for sale in Mill View, Ball Green,, More detailed grinding machine, coal Ball ...

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as .

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

For detailed descriptions of all the parts, how I built it, and how I use it, read further down this page. The drum I used for the ball mill was originally a plastic container that held abrasive grit used in vibratory tumblers. It is about two liters in size. I had several empty containers of this type, and decided to .

IQS Directory implements a thorough list of ball mill manufacturers and suppliers. Utilize our listing to examine and sort top ball mill manufacturers with previews of ads and detailed descriptions of each product. Any ball mill company can design, engineer, and manufacture ball mills to meet your companies specific qualifications.

The typical mill used for these purposes has been the high energy ball mill such as tumbler ball mills, vibratory mills, planetary mills, and attritor mills (Szegvari attritor) etc. A detailed description of the different mills available for MM can be found in Suryanarayana handbook [25]; however we have discussed a brief description regarding ...

We often need grinding operations in the metallurgical industry. The various components of the ore were separated from each other for minerals processing plant after grinding in ore mining industry. Ball mill is often used in processing the slag. If the fineness of products cannot reach the requirements after grinding, the unit separation between the ores will be not

Make a Ball Mill in 5 Minutes: This is for all the pyro nuts that I came across on Instructables. This can be used to grind chemicals to a very fine grain or to polish says "A ball mill is a type of grinder used to grind materials into extremely fine powder for use i...

Stirred Mills have been proven to provide energy savings compared with traditional ball mills. The finer the product required, the more efficient stirred mills will be than a ball mill. The attrition grinding action, vertical arrangement, and the finer media size distribution contribute to make stirred mills more energy efficient grinding machines.

The Ball Mill System (BMS) is a strongly coupled MIMO system,in order to implement a longterm automatic operation of the BMS effectively,and improve the automation level and efficiency, the paper present the overall design of the system,the control system is composed of Siemens SIMATIC S7400PLCS7200PLC,the PROFIBUS DP protocol and MPI protocol are both employed to setup a DCS .

detailed outline of each step of the retrofit. Additional measures (, checking the lift before running the mill, installing a new gear guard) were taken to ensure optimal safety. And to minimize downtime and help guarantee efficiency over time, the mine is keeping spare parts, filters and trunnion seals in stock.

Ball Mills. IQS Directory is a top industrial directory listing of leading industrial ball mill manufacturers and suppliers in Pennsylvania. Access our comprehensive index to review and source ball mill manufacturers with preview ads and detailed product descriptions.

WhatsApp)

WhatsApp)