How should we do to optimize a cement ball mill? Quora

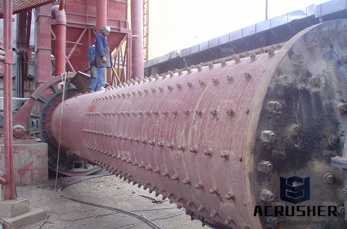

Telephone: Contact Person: Fax:— In the production process of cement ball mill, the mill is one of the key equipment for manufacturing cement. The power consumption of the mill accounts for...

WhatsApp)

WhatsApp)

Telephone: Contact Person: Fax:— In the production process of cement ball mill, the mill is one of the key equipment for manufacturing cement. The power consumption of the mill accounts for...

Dec 10, 2004· Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time ... Furthermore, it has shown that a L/D ratio of about, which is a quite common value for cement mills, might be to high for a ball mill in a Combigrinding plant. This was proven by the ...

Mar 24, 2019· The mill is equipped with a discharge diaphragm at the end. Cement Mill Operation China Pdfcement mill operation china pdf USD Cement ball mill design pdf 12 Sep ball mill design pdfindia for saleprice process crusher cement ball. The optimization of this process would yield substantial benefits in terms of energy savings and capacity increase.

Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with...

CEMENT BALL MILL OPTIMIZATION FILETYPE PDF. Jun 19, 2019· For the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Home Mill equipment cement ball mill optimization filetype pdf.

ball mill optimization siam cement group icidret. Eurasc New Members Professor Saffa Riffat University of Nottingham (United Kingdom) Professor Riffat holds the posts of Chair of Sustainable Energy and Head of Buildings, Climate and Environment Research Group at the University of Nottingham, UK.

Optimization of Cement Grinding Operation in Ball Mills. Optimization of Cement Grinding Operation in Ball Mills Several energy efficient options for cement grinding are available today such as vertical roller mills, roller presses (typically in combination with a ball mill), and clinker pregrinders with.

Jul 06, 2019· Circuit sample analysis and mill chambers sample analysis indicates performance of the separator and progress of the grinding process along the length of the mill. Cement ball mills typically have two grinding chambers. The second chamber is the fine grinding chamber.

Optimization of the Cement Ball Mill Operation At the same time, the vertical mill raw meal grinding process is a complex. Cement Bakl Operation China Pdf. How Raw Mill Working Pdf. Compare this with the milling progress as presented in Figure 2 after optimization. Raw mill is also called raw material mill, which is the key equipment for ...

Jun 19, 2019· For the cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding. Home Mill equipment cement ball mill optimization filetype pdf.

The present invention relates to a soft ball cement mill particle size measurement method. Select the auxiliary variables: the separator speed, feed rate and inlet pressure separator, classifier load as measured auxiliary variables soft finished model size. Data Pretreatment: filtering the raw data, filtered and standardized. Based Soft Sensor Modeling (genetic algorithm optimization neural ...

Pulverizer Ball Mill Optimization, ball mill optimization siam cement group;, 2012 coal pulverisation with vertical roller mills http //ww23, Contact Supplier. Get Price And Support Online; optimization of vertical roller mill in cement industry. Grinding process optimization — Featuring case studies and .

Optimization Ball Cement Mill cement ball mill optimization filetype pdf A cement mill or finish mill in North American usage is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement.

Optimization of mill performance by using online ball and pulp measurements Soon after a stop, a mill is a dangerous place to enter for the personnel tasked with taking measurements or samples. Crash stops are difficult to handle. The mill and all feed streams should be stopped simultaneously but, often, they are stopped around about the same time.

4. MILL LOAD CONTROL LATEST CONCEPT FOR CEMENT MILL OPTIMISATION Concept M/s Holderbank Engineering, Canada has developed a control strategy for ball mills which can maintain a mill production near optimum, with little operator intervention. .

May 11, 2015· a grinding mill which consumes 6070% of the total electricity consumption of the cement plant[12]. A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder. Grinding Aids are used to improve the grinding efficiency and reduce power consumption. This paper discusses the grinding aids mechanism and

Optimization of the Cement Ball Mill Operation Optimization addresses the grinding process, maintenance and product quality. Vertical roller mill feature and working .. The mill is equipped with a discharge diaphragm at the end. The rotation of the grinding table acceler. Cement mill ore crusher priceA cement mill or finish mill in North ...

Jul 31, 2014· Mill power draw prediction can be carried out using Morrell''s power model for tumbling mills (Morrell, 1998). Bond method The established technique for determining power requirements for ball mills is the Bond method (Bond, 1961). This method also involves the application of some ''efficiency factors'' as described by Rowland (1975).

Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time

Cement mill sizing. Mill ventilation. Heat balance. Water request. Temperature. Cyclone sizing. ... but Users need a certain experience to implement results of these calculators . Sizing equipments and mill''s optimization are the job of material suppliers and experienced engineering offices. Mono ch. mill (visible plates) ... Ball mill''s ...

Ball Mill Cyclones Weight Feeders Recycling Elevator Sep. Feed Mill Feed Sep. Return Final Product System Fan Figure 1: Closed circuit grinding system. milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement .

Based on a dynamical model of the grinding process in closed circuit mills, efficient efforts have been made to optimize PID controllers of cement milling. The process simulation is combined with an autoregressive model of the errors between the actual process values and the computed ones. Long term ...

Download Citation on ResearchGate | Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time ...

The plant has 2 cement mill systems that were producing blended cement. One cement mill system (CM1) produced approximately 65 mt/h of cement and the second cement mill system (CM2) produced approximately 20 mt/h of cement. CM1 is a ball mill in closed circuit with a high efficiency classifier and a pregrinding system.

WhatsApp)

WhatsApp)