MAKING ALUMINUM POWDER SUPER REACTIVE .

Jul 26, 2017· Making aluminum powder with only some aluminum foil, the ball mill jar we built last video, and some steel balls! Perfect for use with thermite, tannerite, or flash powder, this process will ...

WhatsApp)

WhatsApp)

Jul 26, 2017· Making aluminum powder with only some aluminum foil, the ball mill jar we built last video, and some steel balls! Perfect for use with thermite, tannerite, or flash powder, this process will ...

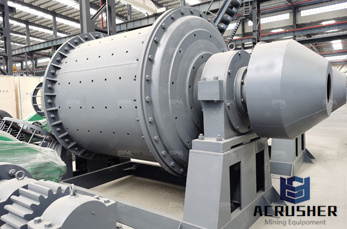

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Ball Mills Steel Ball Mills Lined Ball Mills. Particle size reduction of materials in a ball mill with the presence of metallic balls or other media dates back to the late 1800''s. The basic construction of a ball mill is a cylindrical container with journals at its axis.

Everything you need to make your own black powder!Instructions are provided with this project.

Ball mills are among the most variable and effective tools when it comes to size reduction of hard, brittle or fibrous materials. The variety of grinding modes, usable volumes and available grinding tool materials make ball mills the perfect match for a vast range of applications.

This mill is going to come in really handy for lots of future projects. I hope this page gives helpful ideas to anyone in need of a ball mill. They are quick, easy, and cheap to build yourself. I need to add a disclaimer here for anyone thinking of using this sort of ball mill for milling gunpowder or other flammable or explosive powders.

Ball milling is suggested as a novel method for enhancing filler dispersion in different matrices that is environmentally and economically sustainable [85]. It is a solidstate mixing of powders, usually performed with ball mills, which enables intimate mixing of .

CoorsTek grinding media (ball mill media) is manufactured from highly durable materials specifically formulated to ensure consistent performance for your bulk material preparation. We can help with your standard and custom applications.

For chemical and physical analytical methods such as AAS, NIR, ICP or XRF it is essential that the specimen is perfectly homogenized to an adequate degree of analytical fineness. A reliable and accurate analysis can only be guaranteed by reproducible sample preparation.

Ball mill Wikipedia A ball mill is a type of grinder used to grind, blend and sometimes for mixing of materials for use in mineral dressing pr. Largescale crushing screening milling plants. Offer efficient, costeffective services for you. ... ball mill for chemical.

.planetary ball mill is a benchtop unit designed to pulverize soft, fibrous and brittle materials. The mill develops extremely high centrifugal forces resulting in energy input that is up to 50% higher than in other planetary ball mills. It has a single grinding station for grinding jars with a.

Jul 23, 2008· A simple home made ball mill for grinding chemicals to make black powder. If you are going to make your own fireworks you will be using lots of black powder. make a lot at a time! Build and use at ...

Common types of grinding mills include Ball Mills and Rod Mills. This includes all rotating mills with heavy grinding media loads. This article focuses on ball and rod mills excluding SAG and AG mills. Although their concepts are very similar, they are not discussed here. Photographs of a glass ended laboratory ball mill show action of ball mass within the mill. The action of other grinding ...

Nov 18, 2008· Summary The Ball Mill is designed to grind materials by turning the cylindrical shell with grinding medium ( steel balls) put in the shell, and has a simple structure and ease of handling. Furthermore, The Ball Mill of a large capacity has been available to a very extensive range of applications in both dry and wet 14. References 1.

A wide variety of chemical ball mill options are available to you There are 12086 chemical ball mill suppliers mainly located in Asia The top supplying countries are China South Korea and India which supply 99 1 and 1 of chemical ball mill respectively. More Details small chemical ball mills for sale

Aug 11, 2007· Grind a mixture of chemicals so that they will react faster when you put them in a furnace or otherwise heat them. Grind glass for use as a distillation column packing material. Here is a short clip of the ball mill in action with the saftey cover installed:

Ball Mills, Buy Fireworks Tools Like Ball Mills, Cannon Fuse . Ball Mill | Skylighter Fireworks Making Chemical milling, that is, reducing the particle size of powdered chemicals .

Process engineering with planetary ball mills Chemical. Planetary ball mills are well known and used for particle size reduction on laboratory and pilot scales for decades while during the last few years the application of planetary ball mills has extended to mechanochemical approaches.

Jul 20, 2019· Pharmaceutical uses of Ball Mill. The small and average capacity Ball mills are used for the final grinding of drugs or for grinding suspensions. The maximum capacity Ball mills are used for milling ores prior to manufacture of pharmaceutical chemicals. Advantages of Ball Mills

In all ore dressing and milling Operations, including flotation, cyanidation, gravity concentration, and amalgamation, the Working Principle is to crush and grind, often with rob mill ball mills, the ore in order to liberate the minerals. In the chemical and process industries, grinding is an important step in preparing raw materials for subsequent treatment.

Laboratory Ball Mills; ... They are used for wet or dry grinding, mixing and blending of ores, chemicals, ceramics, glass and more. Benchtop Labmill is lightweight and compact, and easily adjusts to four sizes of milling jars, 16320oz (–10L). Jars made of High Density Polythylene fit in metal reinforcing sleeves and are disposable to ...

The ball mill consists of the mill base and the mill jar. There''s one more important component to a ball mill, though: the media. The balls of heavy material which fall upon and crush the chemicals are called the milling media.

Mar 29, 2019· How to Make a Ball Mill. Ball mills are a special instrument used to break up hard solids into a fine powder. They are similar to rock tumblers in that the instrument is a rotating container filled with heavy balls to grind the substance...

A ball mill is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints. Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium. Different materials are .

WhatsApp)

WhatsApp)