Threeroll mill grinding paint YouTube

Sep 05, 2013· This feature is not available right now. Please try again later.

WhatsApp)

WhatsApp)

Sep 05, 2013· This feature is not available right now. Please try again later.

After the wetting stage, it is necessary to deaggregate and deagglomerate the pigment particles. This is usually accomplished by mechanical action provided by high impact mill equipment. In the grinding stage, the cohesive forces inside the agglomerates have to be overcome.

Jul 01, 2003· This is achieved by changing the grinding media, process milling method or using a more efficient mill. The specific energy requirement is the best parameter for choosing the most efficient mill. The mill that works at the lowest specific energy will save you the most time and money over the life of .

Vibratory Grinding Mills Size Reduction Equipment SWECO also carries a full complement of parts and accessories for the VibroEnergy Grinding Mills. Ancillary features include components such as SWECO''s newly developed door plug, FDA linings for sanitary applications, and various grinding pots for smaller lab size units.

The Zeta ® grinding system is, in every respect, a user friendly, lowmaintenance and very reliable grinding system. Starting with the structural design of the agitator mill, there is already a number of advantages: the horizontal orientation guarantees a homogeneous fill of the grinding media in the grinding .

Paint is a coating material based on organic binders and, depending on the composition of the binding agent, can contain organic solvents and/or water. The organic or inorganic pigments that are finely dispersed in the binder give the paint its color. In general, paint is composed of binders, solvents, fillers, pigments and additives.

The multifunctional laboratory mill LabStar enables scientific academic work even at difficult research and development tasks and convinces by easy handling. The laboratory mill LabStar is the smallest grinding unit of NETZSCHFeinmltechnik that enables an exact scaleup to comparable production machines.

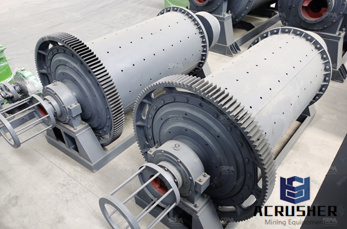

JoyalGrinding Mill,Fine Grinding Mill,Micro Powder Mill,Ultrafine Mill,Raymond Mill From China page is about the grinding mill,includes micro powder mill,high pressure mill,ygm model,raymond mill,3r,4r,5r,6r and ball mills,if you want to buy these joyal grinding mills.

Digital Remastered Edition Coffee Mill Original Blue Painting. Juan Gris. 22. More from This Artist Similar Designs. Digital Remastered Edition Coffee Mill Painting. Juan Gris. 22. ... Tea Pot And Spice Grinder Painting. Janet Poirier. 27. More from This Artist Similar Designs. Coffee Grinder Wall Painting. Alison Stein. 17.

A wide variety of paint grinding machine options are available to you, such as free samples, paid samples. There are 13,451 paint grinding machine suppliers, mainly located in Asia. The top supplying countries or regions are China, South Korea, and India, which supply 99%, 1%, and 1% of paint grinding machine respectively.

Hockmeyer specializes in wet grinding and dispersion mills including basket, media and immersion mills used for particle reduction in the paint, ink, ceramics, inkjet, proppants and cosmetics industries.

Apr 19, 2017· Solvent Paint Mixing Trial Axial flow Impeller vs High Speed Disperser impeller Duration: 24:57. Greaves Mixers and Pressure Vessels 28,158 views

The particle size is an important dye performance indicator and is usually increased by the manufacturer through a grinding process. The finer the paint, the stronger the adhesion. The smoother and finer the film appearance, the less dye consumption is utilized. Shown here are the results of ultrafine paint grinding using our grinding mills.

Aug 18, 2015· Effective bead mill for coating . catherine ... Paint Bead mill machine Mixer Grinder Machine. Loading... Unsubscribe from Mixer Grinder Machine? Cancel Unsubscribe. Working...

As one of the most professional wet grinding mill manufacturers and suppliers, we warmly welcome you to wholesale costefficient wet grinding mill for sale here from our factory. For price consultation, contact us. ... Paint: Car Paint, Finish paint, Wood paint, Industrial paint;

offers 424 paint grinding mills products. About 68% of these are grinding equipment, 6% are mine mill, and 6% are mixing equipment. A wide variety of paint grinding mills options are available to you, such as free samples.

offers 13,205 grinding machine for paint products. About 32% of these are grinding equipment, 2% are mine mill, and 1% are flour mill. A wide variety of grinding machine for paint options are available to you, such as surface grinding machine, cylindrical grinding machine, and .

Uused to indicate the fineness of grind or the presence of coarse particles or agglomerates in a dispersion. ... paint, ink, adhesives, etc. ... Long roll jar mills are designed specifically for applications where space is at a premium. Grinding Mill Jars: Grinding Media:

As you know, too coarse a grind and you are likely to face issues with your paint color uniformity, gloss and opacity. In the industry, the fineness of grind is generally achieved with a 2step process, using first a dissolver, then a pearl mill.

The laboratory mill LabStar is the smallest grinding mill of NETZSCHFeinmltechnik that enables an exact scaleup to comparable production machines. Depending on the application, three stateofthe art grinding systems – Zeta ®, Discus and Neos are available in different material designs.

offers 6,101 grinding mill for paint products. About 1% of these are building coating, 1% are car paint, and 1% are furniture paint. A wide variety of grinding mill for paint options are available to you, such as appliance paint, furniture paint, and building coating.

Ask for the different kind of grinding. Turn key solutions and equipment for the manufacturing processes of paint, coatings, inks and adhesives ... The most widely used process in the word for all types of millbase grinding for [...] Supermill EHP Supermill Plus Optimill.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

The ConJet ® highdensity bed jet mill is a spiral jet mill combined with a patented dynamic air classifier. This classifier enables the ConJet ® to achieve highest finenesses independent of the product load, and therefore also highest throughput rates. Applicable for finenesses from to 70 µm (d97). Machine sizes available for grinding air volumes from approx. 50 to 2,400 Nm³/h.

WhatsApp)

WhatsApp)