Pulverizers 101: Part I POWER Magazine

Jul 31, 2011· Pulverized coal mills with throats that are too wide will have corresponding low throat velocity in the mill grinding zone that contributes to excessive coal rejects and fires. This is an .

WhatsApp)

WhatsApp)

Jul 31, 2011· Pulverized coal mills with throats that are too wide will have corresponding low throat velocity in the mill grinding zone that contributes to excessive coal rejects and fires. This is an .

In coalfired power plants coal mills are used to pulverize and dry to coal before it is blown into the power plant furnace. The coal is feed into the coal mill through a central inlet pipe where gravity is used to lead the coal to the bottom of the mill, where the grinding table and some heavy rollers pulverizes the coal .

Coal Mill, Coal Mill Suppliers and Manufacturers at . Product Name Coal Grinding Mill manufacturer Model YGM7826 model Color White, Yellow, Blue, Red Standard CE ISO Capacity 25500kg/h based on different hardness materials Motor power .

types of coal mill in power plant | worldcrushers. Apr 27, 2013· Coal powder mill applied at coal fired power plant and thermal coal power plant and other plants. . It has become the most common types of grinding machine. Coal mill manufacturer China|Coal .

pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

Thermal power plant vertical coal mill grinding roller and table. Editor: Because of the obvious energysaving advantages of vertical roller mill, more and more cement and building materials companies choose it to grinding .

Sep 11, 2013· LOESCHE coal grinding mills are distinguished by characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations. Special ...

Coal dust is a type of fine coal powder ground by coal grinding mill, size range ~, and most of powder''s size range 20~50μm. Pulverized coal processed by grinding machine could be fully burned, use ratio very high, and we have provided technical support for many power plant.

Coal Grinding Mill Used In Power Plant. Home products how many tons can a rock crusher per hour. . of the tons per hour it can produce . crusher for sale in 80 ton per hour gravel . get price and support online how many tons produced by crusher how many ton per hr will a x crusher produce how many tons per hour can a jaw crusher produce rock crushing 100, .

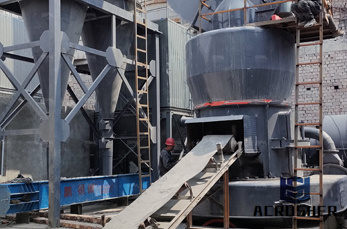

Vertical coal mill, also known as vertical roller coal mill and vertical coal grinding mill, is a mechanical equipment for crushing and grinding coal into coal power. It is an important auxiliary equipment for pulverized coal furnace, rotary kiln and other kilns which need pulverized coal as fuel.

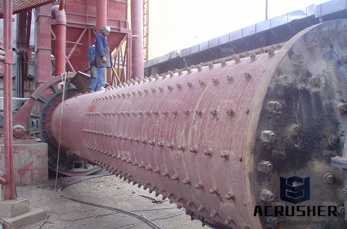

PRINCIPLES OF GRINDING Raw Coal is fed into the Mill for Grinding. Grinding takes place by Impact and attrition. MILL DETAILS. Design coal capacity Tons/Hr Ball charged 90 Tons Speed 15 to 16 rpm Screw assebly Right hand helix(DE side) Left hand helix (NDE side) Direction of rotation from NDE end Clockwise. Shell door opening two ...

Coal Mill is major equipment of cement plant and used for drying and grinding coal. efficiency improvements in coal fed utilities SHMG series coal mill products are recognized as Chinese Famous Brands. feeding, crushing, homogeneous mixing, vertical mill, rotary kiln, cement mill, coal mill, press require to produce large heat exchanger of ...

pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal .

In coal milling for power stations, a ''closedloop'' process is used in which the rejects from the classifier are returned to the mill for regrinding. In VSMs, the recirculation loop is within the mill, but some mill types would have an external loop. In fact, there are a number of recirculation loops within a mill system.

Coal processing plants include coal grinding mill, coal crushing plant, coal screening plant and coal belt conveyor, etc and SBM supply all kinds of those coal processing plants. Coal crusher is widely used in the coal crushing process.

Coal Grinding Cost And Power. considers coal preparation in gasification plants LOESCHE coal grinding cost and power,Loesche vertical roller mills deliver cuttingedge throughput rates and operating efficiency for the cement, iron steel, energy, demand for coal grinding and drying has also increased However, coal preparation has often been mill .

Nov 13, 2016· The initial process in coal based thermal power plant is coal Function of coal Handling Plant in thermal power plant is to receive,process, store, feed the coal bunkers consistently over entire life of the power plant. Coal is transported in thermal power station either by railways,roadways or rope ways.

VM series Vertical Grinding Mill is a kind of large scale powder mill which is designed specially to solve the problems of low capacity and high consumption of industry mills. ... Coal Mill Structure In Power Plant Mozambique ... OverviewExisting Coal Mining ProjectsPossible Coal ProjectsCoal InfrastructureProposed CoalFired Power ...

Hammer Coal Mill In Power Plant Familienurlaubmit. Hammer coal mill in power plant hammer coal mill in power plant pulverizer wikipedia a pulverizer or grinder is a mechanical device for the grinding of many different types of materials for example a pulverizer mill is used to pulverize coal .

e mill gear box for coal grinding in power plants Henan. E Mill Gear Box For Coal Grinding In Power Plants 01 Calcite Deep Processing Plant in Belgium 800 meshes =D90 Calcite deep processing production line in Belgium is composed of PE250400 jaw crusher, electrovibrating feeder, HXM1021 micro powder mill, hoister, electrical cabinet, packing machine and pulse dust collector.

Jul 31, 2011· Pulverized coal mills with throats that are too wide will have corresponding low throat velocity in the mill grinding zone that contributes to excessive coal .

Pulverizer Wikipedia. A pulverizer or grinder is a mechanical device for the grinding of many different types of materials. For example, a pulverizer mill is used to pulverize coal .

1990 Central coal grinding plant (LM D) for gas and steam power station (coal gasification). 1992 Central coal grinding plant (LM D) for the production of lignite (brown) coal dust. 2002 Coal grinding plant (LM D) for grinding wood pellets for power stations. 2005 First 4roller pressure mill (LM D) becomes available ...

The firing and cofiring of biomass in pulverized coal fired power plants around the laboratory mill types; cutting mill (CM), hammer mill (HM) and impact mill (IM). The specific grinding energy .

WhatsApp)

WhatsApp)