The Mining Process at Copper Mountain Mine YouTube

Oct 11, 2013· The Mining Process at Copper Mountain Mine CopperMountainMining. ... Modern Process of Plywood Processing Line ! ... OPEN PIT MINING OF COPPER IN THE AMERICAN SOUTHWEST 1960s .

WhatsApp)

WhatsApp)

Oct 11, 2013· The Mining Process at Copper Mountain Mine CopperMountainMining. ... Modern Process of Plywood Processing Line ! ... OPEN PIT MINING OF COPPER IN THE AMERICAN SOUTHWEST 1960s .

Bulyanhulu Mine can process million tonnes of underground ore per year and, through the flotation process, remove most of the waste rock and concentrate the minerals into approximately 25,850 tonnes of concentrate containing gold and copper. That is nearly a 40 times reduction in .

Common copper ore concentrate equipment of copper processing plant is a traditional thickener, efficient deep cone thickener, inclined plate thickener; common filter used in a copper mining process plant are disc vacuum filter and a ceramic filter. Xinhai company has .

Jun 16, 2014· The flotation machine is used for the separation of the nonferrous black metal as well as the separation of the nonmetallic materials such as the coal fluorite and the talc.

The Oxygen Flash Furnace At the Asarco copper smelter in Hayden, Arizona, the oxygen flash furnace is initially heated up with natural gas. It becomes so hot that the copper concentrate immediately ignites when it is blown into the furnace along with oxygen and a silicabearing flux.

Increasing the efficiency of copper concentrates production, smelting and electrolysis is possible by carefully selecting the optimal valves for each process. The most common copper ore types, copper oxide and copper sulfide, undergo two different refining processes – hydrometallurgical and pyrometallurgical, respectively.

Copper is produced in the U. S. primarily by pyrometallurgical smelting methods. Pyrometallurgical techniques use heat to separate copper from copper sulfide ore concentrates. Process steps include mining, concentration, roasting, smelting, converting, and finally fire and electrolytic refining. Process Description24

Toowong Process–The Toowong Process is being developed by Core Resources, Brisbane, Australia. It is a patented alkaline leach process for the removal of arsenic, antimony and other penalty elements from copper, lead and nickel sulphide concentrates, and antimony from gold concentrates.

The greenish powder that remains once the water content of the froth has evaporated is copper concentrate. But it''s not pure copper yet, it''s a copper iron sulphide, made up of about 35 per cent pure copper. Now, it''s ready for smelting. Copper concentrate is fed into the ISASMELT furnace, where it is heated to 1185 degrees Celsius.

Global production of copper concentrates is expected to increase by 3% yearonyear from 2015 2024. Arsenic is the main impurity present in copper concentrates, and is predicted to be above penalty limits in 10% of all copper concentrates produced in 2015.

Place these products in the extraction process in ascending order of copper content. Use the flow chart as a guide: Matte Ore Cathode copper Blister Anode copper Copper concentrate Fire refined copper; Use a periodic table to find the atomic masses of the elements in cuprite and chalcocite. Then work out the percentage of copper in each mineral.

David Duckworth of consulting company Saint Barbara notes that "the issue of higharsenic (highAs) copper concentrates has been highlighted recently with the startup of a number of new projects producing this material. "Copper concentrates can be divided into clean or complex types," he writes in the company''s latest newsletter.

The TLP extracts copper directly to cathodes from concentrate solution using electrolysis. Since inception of the mine, refractory ore from the copper production process was surface stockpiled. KCM has now developed a process to extract copper from the refractory ore stockpile.

Copper processing is a complicated process that begins with mining of the ore (less than 1% copper) and ends with sheets of % pure copper called cathodes, which will ultimately be made into products for everyday most common types of ore, copper oxide and copper sulfide, undergo two different processes, hydrometallurgy and pyrometallurgy, respectively, due to the different ...

Aug 05, 2011· PROCESSING COPPER ORE IN KITWE ZAMBIA ... by the purchase of some 18,000 tons of copper in highgrade oxide concentrate bought from the Democratic Republic of the Congo. ... The Mining Process at ...

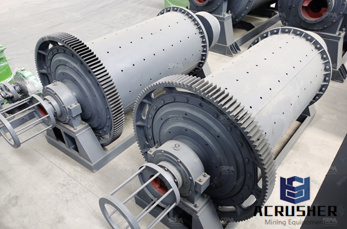

The copper ore usually contains a large amount of dirt, clay, and a variety of noncopper bearing minerals. The first step is to remove some of this waste material. This process is called concentrating and is usually done by the flotation method. 3 The ore is crushed in a series of cone crushers.

Copper From Beginning to End. Copper is a major metal and an essential element used by man. It is found in ore deposits around the world. It is also the oldest metal known to man and was first discovered and used about 10,000 years ago. And as alloyed in bronze (coppertin alloy) about 3000 BC, was the first engineering material known to man.

About 80 % of primary copper production comes from lowgrade or poor sulfide ores. After enrichment steps, the copper concentrates are usually treated by pyrometallurgical methods. Generally, copper extraction follows the sequence (see Figure below): 1. Beneficiation by froth flotation of ore to give copper concentrate

MINING TO SMELTING GOLD/COPPER CONCENTRATES IN DETAIL INTRODUCTION Rocks are mined and then trucked to the process plant Acacia operates three gold mines in Tanzania: Bulyanhulu Gold Mine, Buzwagi Gold Mine and North Mara Gold Mine.

Oct 21, 2014· A new report by GFMS, a metals and mining consultancy, ... There is not a a proven hydromet option to replace the smelting process of copper concentrates. There are several technoligies still in ...

Cobalt extraction refers to the techniques used to extract cobalt from its ores and other compound ores. Several methods exist for the separation of cobalt from copper and depend on the concentration of cobalt and the exact composition of the used ore

Copper mining in the United States has been a major industry since the rise of the northern Michigan copper district in the 1840s. In 2017 the United States produced million metric tonnes of copper, worth 8 billion, making it the world''s fourth largest copper producer, after Chile, China, and Peru. Copper was produced from 23 mines in the US.

The dried copper concentrate of about 28 percent copper is shipped to the smelter. It represents less than one percent of the material removed from the mine. Concentrate is just a fine powder of the mineral chalcopyrite which is a naturally occurring compound of copper, iron, and sulfur.

Copper in the USA: Bright Future Glorious Past Copper Producers. At the beginning of copper''s flow through the economy are the mining companies, which process vast quantities of lowgrade ore, mostly from openpit mines in order to produce copper. Approximately two tons of overburden must be removed along with each ton of copper ore.

WhatsApp)

WhatsApp)