Dryers Equipment Tarmac International, Inc.

assumes 6% moisture by total weight, 350 ft/min gas velocity, 220 f material discharge temperature, 100 lb/ft3, 500′ elevation. lower moisture levels will increase .

WhatsApp)

WhatsApp)

assumes 6% moisture by total weight, 350 ft/min gas velocity, 220 f material discharge temperature, 100 lb/ft3, 500′ elevation. lower moisture levels will increase .

Buy a Gold Processing Plant Many of our socalled small gold mines or low grade deposits could well take this simple and inexpensive flowsheet for an example and be rewarded by a good profit per ton of ore treated, if the owners or operators would adhere to these principles.

A motorized drywashing machine is excellent for the production demands of a one or twoperson operation. Under ideal conditions, it is able to process up to about a ton of raw material per hour, which is the equivalent of what a mediumsized wet sluicing operation can produce.

GOLD PROCESSING PLANTS. Portable placer gold processing plants for alluvial mining, screen deck classifying jigs for alluvial dredging and mining, self contained gold processing plant, fine gold recovery, gold processing plants, gold processing plant, mine plant, mining plant, mining plants, placer gold recovery plant, gold processing plants, GOLD, PROCESSING, PLANTS.

The process takes 20 oz per ton sliver galena ore and concentrates it up to 1,800 oz. per ton. The entire plant was designed and built by Paul Clift and TriR Engineering. HelixSpiral Gold Concentrators .

Portable Gold Wash Plant. Welcome to GWP, where we make highquality, affordable gold wash plants for sale. Our product lineup is designed to efficiently handle anywhere from 30 to 300 tons of material per hour. Each wash plant has three proportionately sized sluice boxes designed to optimize gold .

Screening allows reducing investment and operating costs, and increasing the products quality with a rapid and large volume processing. DOVE offers the largest range of Trommel Screens of different types and specifications, with a wide range of the processing capacities from 6 tons/hour up to 1000 tons/hour, per single Trommel Screen.

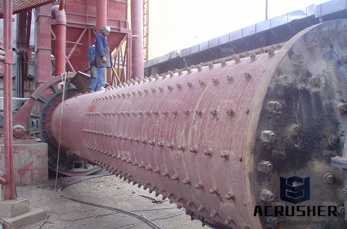

Small Mini Ball Mill 1 Ton Per Hour/grinding Ball Mill Cement Gold Processing Machine Prices, Find Complete Details about Small Mini Ball Mill 1 Ton Per Hour/grinding Ball Mill Cement Gold Processing Machine Prices,Gold Processing Ball Mill,Small Ball Mill,Mini Ball Mill from Mine Mill Supplier or ManufacturerHenan Xingyang Mining Machinery Manufactory

New and Used Gold Recovery Trommels for Sale Savona Equipment is your source for New, Used, and Reconditioned Trommels for recovering gold and other precious metals from placer mining operations. We supply 18 inch, 30 inch, 48 inch, 60 inch, 7 foot Trommels for Placer Mining.

More information ..... 150 Ton Per Hour Gold Wash Plant. Get price. Gold Recovery, iCON Gold Recovery, Gravity Concentrators ... The i350 Gravity Concentrator is revolutionizing the world of alluvial gold mining ... At a capacity of 1015 tons per hour solids, the i350 is commonly used for:. ... 1020 Ton/Hr Gold Processing Equipment IGR500 ...

Savona Equipment is one of the leading suppliers of placer mining equipment including gold wash plants. Our Placer mining equipment is used for the mining of alluvial deposits of minerals. Our inventory includes full production Gold Trommels, Gold Placer Plants, and Mining Wash Plants for Gold Mining.

The Mini Gold Trommel Wash Plant is an easily portable Gold Wash Plant that can be towed by an ATV, and can be broken down to its major components in under 1 minute. Complete with 2stage 60" x 10" Sluice box this Trommel features excellent gold recovery.

Portable Gold Diamond Trommel Wash Plant by Heckler Fabrication. 2030+ Tons Per Hour. Diesel,Gas, Electric drive options. High capacity and extremely portable gold trommel with easy, quick set up, excellent gold recovery.

gold plant will be that of the leaching and carboninpulp circuit (CIP). The reagent and ... 300 to 20 000 grams of gold per ton of carbon, a concentrating factor of about 1 000–1 500. A portion of the loaded ... The process design of gold leaching and carboninpulp circuits

Nov 06, 2017· APT has been awarded an order for a JCRD100, a hard rock 10 tonne per hour gravity gold recovery plant, heading to Ghana. The client asked for a fast track supply, ergonomic plant to cater for oxidized hard rock free gold on a surface deposit. Emphasis was placed upon having a plant .

SV9 Vibratory Gold Wash Plant. Our vibratory gold wash plant, the SV9, (aka Monster Red) is rated up to 450 tons per hour. This design allows for nuggets and fine gold recovery. The SV9''s horizontal design allows for much lower feed height and improved cleaning action of materials.

GM Processing 60 Ton per hour tantalite process plant. GM Processing 100 Ton per hour spiral plant. GM Processing 100 ton per hour spiral plant with feed system. G M Processing 20 ton per hour Copper spiral plant. Additional Contract Quotations Dam dredging. Heavy media cyclone plant 400 ton per hour. Bin linings.

The IGR 100 Modular Gold Processing Plant is a selfcontained fine gold recovery equipment system. It uses classification and enhanced gravity to assure you are catching the finest gold and the big nuggets. In the standard configuration material flows as follows: The miner feeds sand/gravel into the vibrating screen The screen divides your feed into 2mm plus 2 mm minus size fractions The 2mm ...

per ton of sodium cyanide and enough quick lime to keep the pH of the solution at about At a slurry concentration of 50% solids, the slurry passes through a series of agitated mixing tanks with a residence time of 24 hours. The gold bearing liquid is then separated from the leached solids in thickener

The Goldlands recovery systems integrate a number of innovative extraction technologies with units ranging from startup testing equipment of 1 to 2 Tons per Hour ranging up to units processing volumes of 5, 10, 30, 50, 100, 200, 500 and 1000 Tons per Hour.

Oct 12, 2016· 5ton per hour hard rock processing plant working in Congo Jaw crusher + ball mill + Knelson centrifugal concentrator + diesel generator + water pumps, hoese, valves + control box.

of highgrade ore per year for 8 years. The deposit contains ounces of gold per ton of highgrade ore and can be acquired at a cost of 10 per ton of ore (cost of mining ore at site). A sodium cyanide process is used to extract the gold from the ore, and various other processing techniques are used to produce % pure gold bullion from ...

Estimates of Electricity Requirements for the Recovery of Mineral Commodities, with Examples ... underground cutandfill mining at 1,500 metric tons per day using the carboninpulp leach ... kilowatthour (kWh) per unit basis, primarily the metric ton (ton) or troy ounce. Data contained

Surface/underground mine cost models a variety of sizes/types: theoretical mining operations, flotation milling, carboninpulp, heap leach placer models.

WhatsApp)

WhatsApp)