Graphite | Graphite Grinding | Ceramic Graphite | Graphite ...

26 rows· FerroCeramic Grinding Inc. machines over 15 different materials Graphite Graphite .

WhatsApp)

WhatsApp)

26 rows· FerroCeramic Grinding Inc. machines over 15 different materials Graphite Graphite .

Almost all plane grinding wheels can be used to process graphite. The surface of the grinding wheel must be sharp. When machining large workpieces with high accuracy, it is recommended to use a diamond grinding wheel, which can make the workpiece edge smooth, improve the surface accuracy, and after the grinding wheel grinding, Durable for a ...

Graphite is difficult to grind into a fine particle size because of its often occurrence as flakes and the covalent bonds'' strength within the atomthick sheets that make up graphite. However, two dry grinding Attritors designed and manufactured by Union Process, the SD Series and the HSA Series, as well as our wet grinding batch Attritor S ...

Through regrinding with the stirred mill followed by a twostage cleaning flotation process, a lowgrade graphite concentrate containing % fixed carbon could be refined to a highquality ...

Spherical graphite grinding system: The spheroidization process is the most important step for making cathode anode materials. Prominer has the ability to provide the complete spherical graphite grinding system including primary crushing mill, shaping mill, air classifier and dedusting system.

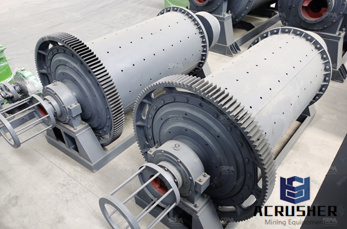

Graphite grinding machine 1ball mill is utilized for grinding coarse graphite ore in the graphite grinding process many ball grinding mills function together 2raymond mill may be the fine grinding machine used for regrinding of concentrate it can grind gr,Grinding Machine For Graphite Price.

Spherical graphite grinding system The spheroidization process is the most important step for making cathode anode materials Prominer has the ability to provide the complete spherical graphite grinding system including primary crushing mill shaping mill air classifier and dedusting system. More Details Graphite milling the proper way EDM Sales

Sep 01, 2000· Today, it is popular to talk of eliminating electrodes for hard die milling. While it is true that the machining process for hardened steel has advanced by leaps and bounds, the production of electrodes (graphite or copper) is, and will remain, a critical process for the production of molds.

Disclosed is a process for grinding graphite comprising: (1) forming a mixture of graphite and a graphite grinding aid; (2) grinding the mixture of graphite and graphite grinding aid to reduce the size of the graphite; (3) forming an aqueous slurry of the graphite particles, graphite grinding aid and water; (4) adding an amount of hydrocarbon oil to the aqueous slurry with agitation to form ...

Miningpedia is a valuable and professional communication platform who focuses on providing mineral processing knowledge, mineral extraction process and the concentration of ore.

The mechanical grinding process for production of ultrafine graphite powders features a simple process, low production cost, and easy to carry out large scale production. We developed a bead mill without a shaft seal and screen to prevent problems caused by traditional grinding.

Even though the vast majority of copper EDM electrodes for injection mold making are machined by CNC machines, knowing how to grind copper is a valuable skill in the surface grinding process. There is always the odd job, or rework that requires manual grinding of copper.

Grinding. Surface grinding — Standard surface grinders can be used with graphite, but the wheels must be kept sharp. The most common grinding wheel used is a green wheel, composed of 60 grit silicon carbide (Norton, Carborundum, Cincinnati, or equivalent tools, medium grade, medium open structure, vitreous bond).

Saturn Industries specializes in graphite CNC Surface Grinding Services. We offer all major grades and manufactured graphite including copper graphite. We offer a full range of surface grinding services such as Regrinding, Precision Form and Flat Grinding holding tolerances up to +/.0001.

Surface grinding nonferrous metals and graphite. Grinding aluminum, copper, brass and graphite all require some special techniques. The nonferrous metals cannot be dry ground, so don''t even try. With some coolant, wax, or kerosene you can grind to your heart''s content though. Graphite is easy to grind, both dry and wet.

Multistage grinding multistage flotation. Xinhai usually applying multistage grinding process to protect graphite flake from damaged. Applying multiple grinding and separation to meet the customers needs. Hydrocyclone can be used at the thickening stage,which keep the grinding density at 40% to 50% for better grinding efficiency.

The different methods of grinding and classification allow for shaping of the particle, giving the graphite distinct characteristics of density and a specific surface. Briquetting. In this process, agglomerated graphite grains are produced for use as carburizer and carbon additives. Intercalation

These machines aren''t just designed with today''s competitive marketplace in mind—we''ve got our eye on the future, anticipating the need for technology that ensures efficiency at every step of the machining process. Makino''s grinding and milling machines are more flexible and capable than ever, and help manufacturers cut cost by ...

Stage 2 Determines the higher pigment content required (Can be performed on lab. shaker Red Devil) Using the % AOWP of Polymeric agent (calculated above) + synergist (if required) prepare a series of millbases with increasing pigment contents in a GRINDING MEDIUM containing APPROXIMATELY 10% SOLID RESIN.

Superfine powder mill is a technological product, which is widely used in the grinding and processing of mineral materials in the fields of metallurgy, building materials, chemicals, mining and other fields. Hongcheng Mine is based on the field of mill manufacturing. The main mill products are: Raymond mill, vertical mill, superfine mill, superfine mill, etc.

News New, Efficient Process for the Rounding of Graphite Extremely small batches for Active Pharmaceutical Substances – with the NETZSCH DeltaVita 1 it''s now possible! The World of DryGrinding and Classifying through the Eyes of Experts NETZSCH is equipped for the future: New safety regulation for tripod and overhead agitators

Process for cleaning Graphite The basket of the wash tank was layered with a rubber mesh so as not to damage the part .The part was then placed into the wash tank and set for a cycle of 5 minutes. After the wash cycle the part was rinsed in deionized water for 3 minutes, rinsing is a very important stage as it neutralizes any left on cleaning ...

To start the process the workpiece is put into the grinding apparatus by hand. Then careful attention is paid to the contours required for grinding to make sure the piece stays in place and the complex grinding is a success. Benefits of CNC Centerless Grinding. Centerless grinding saves a great deal of time through the process.

At present, the graphite beneficiation processes are mainly gravity separation process, froth flotation process, electric separation process and the combination process. And froth flotation process is the main graphite mining process. Generally, 90%97% grade of graphite concentrate can be obtained after the graphite flotation process.

WhatsApp)

WhatsApp)