RAG AG Wikipedia

RAG AG, formerly Ruhrkohle AG, is the largest German coal mining company headquarters are in Essen in the Ruhr company was founded on 27 November 1968, consolidating several coalmining corporations into the Ruhrkohle AG.

WhatsApp)

WhatsApp)

RAG AG, formerly Ruhrkohle AG, is the largest German coal mining company headquarters are in Essen in the Ruhr company was founded on 27 November 1968, consolidating several coalmining corporations into the Ruhrkohle AG.

We present dispersion curves, and amplitudedepth distributions of the fundamental and first higher mode of Love seam waves for two characteristic seam models. The first model consists of four layers, representing a coal seam underlain by a root clay of variable thickness.

The coal seam itself consists largely of plant material with small but variable amounts of mud. The seam itself can vary in thickness from a few millimetres to tens of metres. Immediately above the coal seam there may occasionally be a mudstone containing rare but distinctive marine fossils (for example, brachiopods and cephalopods).

Ruhrkohle AGCentral Drainage Division ABSTRACT ... Coldewey and SemrauMine Water in the Ruhr Area (Federal Republic of Germany) GEOLOGY OF THE RUHR AREA In the Ruhr area, the Upper Carboniferous strata come to the surface in the south and are ... The ratio of coal seam to total thickness increases as we move upwards from the

International Journal of Coal Geology, 9 (1987) 4576 45 Elsevier Science Publishers, Amsterdam Printed in The Netherlands Coal petrography in the Ruhr hard coal industry REINHOLD KUTZNER Ruhrkohle AG, 4300 Essen 1, Germany (Received January 16, 1987; accepted for publication March 18, 1987) ABSTRACT Kutzner, R., 1987.

Coal mining greatly increased during the industrial revolution and the following decades. The main mining areas were around Aachen and the Ruhr area, along with many smaller areas in other parts of Germany. These areas grew and were shaped by coal mining and coal processing, and this is still visible even after the end of the coal mining.

dispersion is not only determined by the thickness of the coal seam and its dirt band content ( thickness and position), but also by ... production of about 3,5 million tons of hard coal. Coal seams are mined with a thickness ranging from about 1,3 m to 3 m. But thin ... SITE DESCRIPTION AND GEOLOGY Seam O lies in a depth of – 1020 m to ...

3. Quantification of Worldwide Coal Reserves . Lignite and hard coal are quantified with the aid of a se ries of cutoff parameters (boundary parameters) as re serves and resources. These include, above all, seam thickness, depth, energy content, interstratified .

Surface mining and deep underground mining are the two basic methods of mining. The choice of mining method depends primarily on depth, density, overburden and thickness of the coal seam; seams relatively close to the surface, at depths less than approximately 180 ft (55 m), are usually surface mined.

the Ruhr area has been one of Germany''s best explored and logged geological regions. ... This is how hard coal mining started in the Ruhr area: in [...] different places the seams could be seen ... at the nothern limits of the Ruhr District, they reach a depth of 1000 meters and more.

This dip below the increasingly thick overburden is interrupted by local tectonic structures, as at the Osning Fault, at the Ibbenbüren Horst or at the Ochtrup Anticline, for example. The Ruhr''s hardcoal deposits are thus only a small portion of the total coal reserves .

Length of boreholes used for destress blasting depends on size of protective area which is created ead of a face and this is a function of thickness of coal seam, size of pillars, mining depth and lockedin stresses in immediate roof rocks (principles are presented in Figure 3).

The goal of coal mining is to obtain coal from the ground. Coal is valued for its energy content, and, since the 1880s, has been widely used to generate electricity. Steel and cement industries use coal as a fuel for extraction of iron from iron ore and for cement production. In the United States, United Kingdom, and South Africa, a coal mine and its structures are a colliery.

Wave propagation in a coal seam is modelled using an algorithm ... Germany 2RuhrUniversity Bochum, Institute of Geology, Mineralogy and Geophysics. 2 Boreholes with depths of 3 m and a drill diameter of 55 mm are adequate for these types of ... and the layering of the coal. Especially the thickness of the coal layer affects the frequency of

RAG AG is responsible for pit water management in the former hard coal mining regions. At the bottom of a former mineshaft hundreds of metres under the surface, the pit water is collected and transported to the surface by powerful pumps and pipes, then channelled into watercourses. The pumping system is designed redundantly.

2 Thick Coal Seams in India 14 3 Depth wise Gondwana coal resources of India 14 4 Maximum vertical stress over pillar, stook and rib for different seam thickness and depth as per numerical model 36 5 Results for depth vs maximum stress in pillars for various depths 37 6 Results for depth vs maximum stress in stooks for various depths 37

High performance remote controlled longwall extraction of low seams exploiting plow systems ... Location of the Prosper Haniel Mine in Germany The coal seam H is located ca. 1000 m below the surface. The average H seam height amounts to m, whereof ... seam. This seam lies in a depth between 300 and 500 m and shows a middle thickness of ...

DSK is a wholly owned subsidiary of the RAG group. RAG group activities are divided into two parts: black RAG, which is related to the German coal mining industry, and white RAG, which deals with chemicals, energy and real estate. Geology and coal quality. All of Germany''s hard coal resources are Carboniferous in age.

Coal mining greatly increased during the industrial revolution and the following decades. The main mining areas were around Aachen, the Ruhr and Saar area, along with many smaller areas in other parts of Germany. These areas grew and were shaped by coal mining and coal processing, and this is still visible even after the end of the coal mining.

Surface mining and deep underground mining are the two basic methods of mining. The choice of mining method depends primarily on depth, density, overburden, and thickness of the coal seam; seams relatively close to the surface, at depths less than approximately 180 ft (55 m), are usually surface mined.

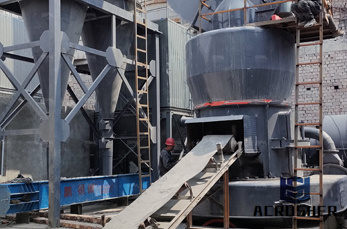

coal mill structure atox km 27 5 coal mill structure atox km 27 5 – Grinding Mill China. densit lining for atox coal mill Stone Quarrying Machine. densit lining for atox coal mill. densit lining for Our company is a leading highend j boring machine equipment supplier, mainly engaged in mine mining machinery equipment.

UNCONVENTIONAL PALEOZOIC GAS RESOURCES in the GERMAN PART of the CENTRAL EUROPEAN BASIN . Ralf Littke and Bernhard M. Krooss . Institute of Geology and Geochemistry of Petroleum and Coal, RWTH Aachen University, Germany (littke) The Paleozoic formations of the Central European basin system, extending from the North

GERMAN MINING INDUSTRY OVERVIEW AT SUSTAINABLE TECHNOLOGIES IN THE MINING SECTOR ... Source: RAG Fuel Minerals –Hard Coal. Longwall Mining with Caving seam thickness 1 m to m depth 800 m to 1,400 m max. 20,000 t /d per longwall automated operation Source: RAG

Mar 01, 2007· During the Pennsylvanian, formation of coal was a phenomenon that was spread over many continents. It is the aim of this paper to illustrate factors that led to the formation of coal seams in paralic clastic sedimentary environments in the Ruhr Basin (German Variscan foreland) during the Pennsylvanian in terms of sequence stratigraphy and the structural evolution of the basin.

WhatsApp)

WhatsApp)