Metalworking: Drilling, Milling, Threading ...

Online shopping for metalworking projects from a huge selection of drill bits, end mills, threaded taps, sanding and grinding tools, and more.

WhatsApp)

WhatsApp)

Online shopping for metalworking projects from a huge selection of drill bits, end mills, threaded taps, sanding and grinding tools, and more.

NEW: Mixer Mill MM 500 vario The first mixer mill worldwide which accommodates 6 grinding jars or adapters RETSCH Laboratory Mills, Crushers and Sieve Shakers RETSCH is the leading solution provider for neutraltoanalysis sample preparation and characterization of solids.

Exporters And Suppliers Of Carbide Tools, Industrial Diamond Wheels / Industrial CBN Wheels, Electro Deposited CBN Internal Grinding Pins, Resin Bonded Diamond Wheels, Resin Bonded CBN Wheels, Resin Bonded Diamond Cup Wheels, Internal Grinding Diamond Pins / Internal Grinding CBN Pins, Internal Grinding Wheels Pins, Electrodeposited Internal Grinding Pins Diamond, Electro .

Hot grinding Hot mills Hot cut Cold grinding Cold cut Bars Cold mills 1 1 2 2 2 3 3 1. Steel Conditioning 2. Large Diameter CutOff 3. Roll Grinding. MATERIAL CLASSIFICATION ... The characteristics and shape of the material dictate the choice of grinding wheel specification.

Highefficiency separators have also found applications in integrated grinding circuits such as vertical roller mill (Roy and Terembula 2003), air classifier mill (Ito et al. 1993(Ito et al ...

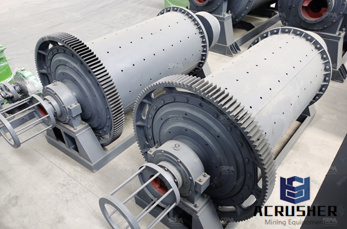

The ball mill is a tumbling mill that uses steel balls as the grinding media. The length of the cylindrical shell is usually 1– times the shell diameter (Figure ).The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weight.

Choose from our selection of wheels, including over 16,000 products in a wide range of styles and sizes. In stock and ready to ship.

Jan 01, 2019· The grinding surface of wheel is expressed by combin ing Eqs. 1 and 2. 3 164 Xianli Liu et al. / Procedia Manufacturing 34 (2019) 161â€"167 Author name / Procedia Manufacturing 00 (2019) 000â€"000 4 Fig. 6: Influences of the controlled parameters rake angle Fig. 7: Different parts of flute grinding with different parts of wheel MwA ...

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of ferrous and nonferrous metals. The ball mill can grind ores and other materials either wet or dry.

''The wheels of the mill are driven by water from the stream and as they turn the whole mill starts to grind and shake with sieves, wheels, drive belts all tied into the water power.'' ''The company compares it to a turning machine that grinds.'' ''But the mills of the gods sometimes grind in an unknown''s favour.''

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

The Planetary Ball Mill Pulverisette 5 allows fast and very fine grinding of hard to soft material, dry or in suspension, down to colloidal fineness. It can also be used for mixing and homogenising of .

Such as power of the spindle drive; grinding wheel dime Process reliability from heavy plate to Work roll µm Ra Grinding wheel dimensions Grinding wheel speed Grinding time per roll Roll type Roll material Roughness Ra [µm] Standard High Performance High chrome – Corundum #36 #46 Corundum Sol Gel #46 Work rolls

As hammer design depends upon the type of work done by the crusher, American hammers are skillfully designed to contribute the greatest efficiency to achieving customers'' requirements. Hammer material can be cast or forged manganese, cast alloy steel, cast white iron, or fabricated from high alloy plate (360–500 Brinell).

Now diamond grinding wheels have advantages in grinding cemented carbide tools owing to its features.. There are resin bond and vitrified bond diamond grinding wheel for tungsten carbide. Resin Diamond Grinding Wheel for Carbide. Resin bond diamond grinding wheel can achieve an ideal grinding effect, but its grinding efficiency is low. For resin diamond grinding wheel, usually use 100 .

Sanding and Polishing Cast Iron Skillet Cookware: First thing, this isn''t a hard project. This process isn''t a one hour project. When finished you will have a piece of cookware that you will love, and wonder why you ever spent the money on a new high cost cast iron pan..

Sep 22, 2018· It''s hard to protect mill ways, as Carl says, and unless you have some way of providing rapid traverse, you''re likely to burn the work What does work OK, provided the spindle bearings are good and you can spin at least 3000 rpm, preferably 45000, is to mount a cup wheel in a drill press and leave the head clamp loose (but the undercollar clamped tight) and swing the whole head, effectively a ...

A grinding wheel is a wheel composed of an abrasive compound and used for various grinding (abrasive cutting) and abrasive machining operations. Such wheels are used in grinding machines.. The wheels are generally made from a composite material consisting of coarseparticle aggregate pressed and bonded together by a cementing matrix (called the bond in grinding wheel terminology) to form a ...

material used for making grinding wheels, sandpaper, abrasive cloth, and lapping compounds. abrasive cutoff A process related to grinding, which uses a thin, bonded abrasive wheel to cut materials for further processing. abrasive disc Disc wheel. A grinding wheel shaped like a straight wheel, but usually mounted on a plate for grinding

We are currently adding 1000''s of new products. Some categories may appear empty at this time.

The grinding wheel is one component in an engineered system consisting of wheel, machine tool, work material and operational factors. Each factor affects all the others. Accordingly, the shop that wants to optimize grinding performance will choose the grinding wheel best suited to all of these other components of the process.

US501433A US501433DA US501433A US 501433 A US501433 A US 501433A US 501433D A US501433D A US 501433DA US 501433 A US501433 A US 501433A Authority US United States Prior art keywords shaft wheels piston crushing cylinder Prior art date Legal status (The legal status is an assumption and is not a legal conclusion.

Totally enclosed DC drive motors permit solidstate control of roll speed. Machines have speed range of between 20 and 300 RPM. Designed with sheet metal pans under each tier of rollers. Pans contain jar contents should spillage or breakage occur. Motors is 115V / 60Hz single phase, (220V / 50Hz also available, call for pricing)

The sJet ® System (patent pending) is a new innovation in a line of consistent developments being made in the area of air jet milling. Final finenesses in the submicron range (example: d 50 µm) can now be achieved with fluidized bed jet mills. As opposed to conventional dry grinding processes with fluidized bed jet mills, the sJet ® System uses superheated steam as its milling gas.

WhatsApp)

WhatsApp)