(PDF) Iron ore sintering. Part 1. Theory and practice of ...

Iron ore sintering. Part 1. ... range, the same that when the BF operate with sinter, with no indication of nonuniform gas ... before the calcination of limestone starts, as a function ...

WhatsApp)

WhatsApp)

Iron ore sintering. Part 1. ... range, the same that when the BF operate with sinter, with no indication of nonuniform gas ... before the calcination of limestone starts, as a function ...

E. Donskoi, ... Manuel, in Iron Ore, 2015. Sinter. Lowtemperature (< 1300 °C) iron ore sinter is an agglomerate of unmelted and partially melted nuclei particles (+ 1 mm) and a matrix bonding phase produced from the melting of fine ore (− 1 mm) and flux particles, with the majority of melt formation occurring in the granule adhering fines layer.

Iron ore is produced in around 30 countries – in 2017, the largest producers were Australia, Brazil and China. Around 98% of iron ore is used in steelmaking. During the ironmaking process, a blast furnace is fed with the iron ore, coke and small quantities of fluxes (minerals, such as limestone, which are used to collect impurities).

Cangem Global can supply both magnetite and hematite iron ore grades. High grade iron ore with Fe % + upto 71% possible. We can supply iron ore Fe 5658% also from India. Cangem can supply iron ore fines, lumps and BF or DRI pellets . There are tons of brokers involved in the industry and unfortunately not more than a small percent of them ...

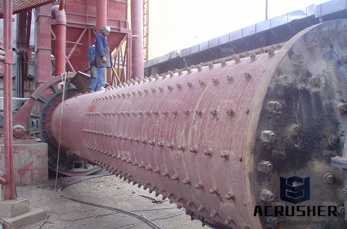

Sinter plants agglomerate iron ore fines (dust) with other fine materials at high temperature, to create a product that can be used in a blast final product, a sinter, is a small, irregular nodule of iron mixed with small amounts of other minerals. The process, called sintering, causes the constituent materials to fuse to make a single porous mass with little change in the chemical ...

Aug 15, 2020· The LibreTexts libraries are Powered by MindTouch ® and are supported by the Department of Education Open Textbook Pilot Project, the UC Davis Office of the Provost, the UC Davis Library, the California State University Affordable Learning Solutions Program, and t. We also acknowledge previous National Science Foundation support under grant numbers,, .

23 In particular, the price of iron ore for Westphalian furnaces near the ore is very similar to the value per ton of ore at the mine in the early 1860s given annually in Prussia, Zeitschrift. 24 For the wage rates of puddlers and rollers in the three countries, see Commissioner of Labor, Fifteenth Annual Report: Wages in Commercial ...

Jun 17, 2020· For iron ore, however, there is an underlying shared interest. China cannot source enough iron ore without Australia and Australia relies on commodity exports for its national budget. The relationship is not as tense as during the Rio Tinto/Chinalco bust up and even then, markets essentially were set not by politics but supply and demand.

The most common steel making technology is the BfBof Route. Coke is used in Blast Furnace (BF) both as a reductant and as a source of thermal energy. It involves reduction of ore to liquid metal in the blast furnace and and refining in convertor to form steel. The various stages of .

World resources are estimated to be greater than 800 billion tons of crude ore containing more than 230 billion tons of iron. The only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it must go through the sintering process. Sinter is the primary feed material for making iron and steel in a blast furnace.

Superior properties of iron ore pellets as compared to traditional iron ore feed materials as lump overs and sinter feed and environmental benefits of iron ore pellets in iron steel making processes. By product, blast furnace (BF) pellets segment is anticipated .

If all the Pilbara''s iron ore miners hit their maximum new export rates, they would ship a combined 15bn worth of additional iron ore, at current prices, and send the total tonnes through ...

This research work focuses on the reduction behavior of iron ore pellets, sinter, and lump ore in simulated BF shaft conditions where H 2 and H 2 O are present in typical CO CO 2 N 2 atmospheres. 2 Experimental Section. Sinter, lump ore, and iron ore pellets were used in experiments. The composition for all three materials is shown in Table 1.

An ideal process would replace the BF and coke oven, would use iron ore concentrates for reasons presented below, and would greatly reduce energy requirements. It should also require much less capital investment than the BF/coke oven combination and must be capable of producing 5000–10,000 tons of metal per day so that it can support existing ...

Aug 21, 2020· Ironmaking, the first step in making steel, involves the raw inputs of iron ore, coke, and lime being melted in a blast furnace. The resulting molten iron—also referred to as hot metal—still contains % carbon and other impurities that make it brittle.

Although level 50 Smithing is required to smith mithril bars, level 60 is recommended so that you don''t have to pay an entrance fee to the Blast Furnace, but this payment is a minor inconvenience. It provides a great opportunity for players to reap great profits by producing a large volume of mithril bars (worth 579 each), which are used by highlevel smiths.

The effect of iron ore characteristics on sintering is mainly through their impact on the granulation and densification processes. With the rapid change in iron ore supplies and composition, steel mills now have to adjust the composition of the ore mixture to their sinter plants more frequently than ever before.

BF with the top gas. To ensure that the iron ore feed has sufficient permeability, strength, and correct size, the fine ore is sintered. Iron ore sintering Iron ore sintering can be described as the controlled burning of a fuel mixed with iron ore (Barker et al, 2006, p. 1393). The process converts natural fine iron ore material, screened

China''s contracting steel industry is hurting iron ore prices because China makes half the world''s steel. And with the health of China''s steel industry deteriorating, Goldman Sachs is forecasting mine closures to accelerate next year.

The blast furnace is still the dominant form of iron production, but over the years, direct reduction methods have increased due to a number of reasons. Overall, iron production methods have optimal requirements with respect to the feed materials especially iron ore. In this study, tests were carried out on Muko iron ore from Uganda to analyse its suitability to meet the feed requirements of ...

Sintering Of Iron Ore Before Bf Processing iron ore sinter youtube the sintering process is a pre, treatment step in the production of iron, where fine sinter crushing and sintering of iron ore before bf sintering of iron ore before. Read More

The charge mix may contain sponge iron as high as 8590%. Sponge iron is produced using iron ore. Along with sponge iron about 1015% pig iron is added in induction furnace. Pig iron is produced using iron ore. A high carbon bath is required to take care of unreduced iron oxide present in the sponge iron.

the size of briquette plays a vital role on reduction material reaching to the Thermal reserve zone of bf it should get reduced and stats lengthy of thermal reserve zone ...

The only source of primary iron is iron ore, but before all that iron ore can be turned into steel, it must go through the sintering process. Sinter is created by mixing iron ore concentrate with several additives such as limestone and silica to control the chemistry and then igniting it .

WhatsApp)

WhatsApp)