Comminution circuits for gold ore processing

Comminution circuits for gold ore processing. ... The chapter describes SAG mill configuration and operation, ballmill circuit operation, gold recovery in comminution circuits, alternate grinding ...

WhatsApp)

WhatsApp)

Comminution circuits for gold ore processing. ... The chapter describes SAG mill configuration and operation, ballmill circuit operation, gold recovery in comminution circuits, alternate grinding ...

CIL is mainly for processing the oxide type gold ore if the recovery rate is not high or much gold is still left by using flotation and/ or gravity circuits. Slurry, containing uncovered gold from primary circuits, is pumped directly to the thickener to adjust the slurry density.

Froth flotation is a process for selectively separating hydrophobic materials from is used in mineral processing, paper recycling and wastewater treatment industries. Historically this was first used in the mining industry, where it was one of the great enabling technologies of the 20th century.

ABSTRACT In this study, simulation aided design of grinding circuit for a gold mine in Iran is presented. The main parameters for the design of the grinding circuit are the ore specifications and ...

Free Gold Recovery. After crushing ore clumps to a manageable size of 20mm or less, via the Python or other crushing circuit, Gekko offers a range of free gold recovery options.. At the coarse 350 micron 20mm ore size, a preconcentration jigging circuit can be designed incorporating a proven, efficient recovery device for free gold: the InLine Pressure Jig.

Natural generation [] Mineral veins []. Gold ore can generate in the Overworld in the form of mineral ore attempts to generate 2 times per chunk in veins of size 9, from altitudes 0 to 32, in all biomes.. Gold ore also attempts to generate 20 times per chunk in veins of size 9, from altitudes 32 to 80, within one of the following biomes, or within a chunk which is at least .

Metallurgical ContentLeaching Gold CircuitsTypical Gold Milling Flowsheets Gold Leaching Equipment LayoutEasy Gold Plant and Business Expansion In Leaching for Gold, there is often a tendency to overlook or minimize the importance of the small mine. The small mine of today may develop into the large mine of tomorrow. Under proper management and financing it has as good a chance of yielding .

gold ore crushing and grinding circuits. Our Purpose And Belief. LM Heavy Industry is committed to provide the global customers with the firstclass products and superior service, striving to maximize and optimize the interests and values of the customers, and build bright future with high quality. All;

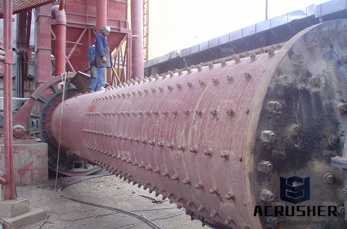

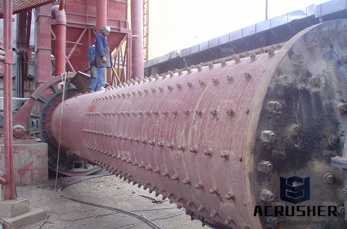

Gold ore processing plant is widely used in gold ore crushing and grinding process to resize and pulverize gold ores into 10mm to smaller than 1mm particles. As gold ore''s VHN hardness is between 60 and 105, SBM design gold ore crushing plant and grinding machine that can process gold ore.

The specific gravity of gold is, so it is times as dense as water. When separating free gold from a typical quartz deposit, gravity concentration must separate based on specific gravities of and, for gold and quartz respectively.

For the vast majority of ounces of gold produced, comminution costs in the form of power, grinding media, and liners represent the single largest cost category of milling. Since, semiautogenous grinding (SAG) ballmill circuits represent the single largest type of gold milling comminution circuits, the chapter focuses on SAG.

OPTIMIZING THE OPERATING CONDITIONS OF GOLD ELUTION AND ELECTROWINNING FOR TAU LEKOA STREAM AT KOPANANG GOLD PLANT ... The mine produces around 450 kg of gold a month. The ores from the mine are ... circuit and get deposited with other base metals in the final product if the elution and electrowinning

Apr 22, 2016· Gravity GoldSelection Sizing The Optimum Circuit. ... reducing gold in circuit lock up and reducing cyanide consumption. ... Gravity gold recovery was mandatory for the oxide ore with % of ...

crusher circuits in gold ore , crusher circuits in gold ore As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. Complex Base Metal Process Plant Circuit

Apr 22, 2016· Gravity GoldSelection Sizing The Optimum Circuit. ... reducing gold in circuit lock up and reducing cyanide consumption. ... Gravity gold recovery was mandatory for the oxide ore .

Home > gold ore flotation circuit > We have the best service. There are various types of mining equipment with green building materials, you can contact us online. Mobile VSI Crusher.

crusher circuits in gold ore crusher circuits in gold ore As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of minerals. Complex Base Metal Process Plant Circuit.

Nov 18, 2013· Salvaging Gold From Old Electronics ... I believe there is about 30 time more gold in a ton of cell phones than there is in a ton of gold ore, the mines that process gold ore isn''t doing it for ...

ore. Relatively coarse gold particles that are liberated from the gangue mineral phase by crushing and grinding are readily recovered by gravity techniques, because of the large difference in specific gravity between gold (SG ) and most gangue minerals (SG 2 to 3). For gold ores that are amenable to gravity separation, recovery of the coarse,

Nov 21, 2018· An ultra high grade gold vein found in a heavily mineralized outcrop! Solid mineral vein panned out to reveal high grade gold, platinum, palladium, silver and other minerals! Vein contains ...

Assuming that a gold ore has been effectively ground to ensure maximum economic liberation of gold, the circuits that will have the most effect on the successful operation of a gold plant will be that of the leaching and carboninpulp circuit (CIP). The reagent and utilities operating costs associated with leaching, adsorption, elution and ...

Gold ore circuit plant. The gold ore is doublerefractory First the gold is locked in sulfide mineral particles that must be oxidized to expose the gold for leaching Second the ore also contains pregrobbing carbon that will collect solubilized gold from the subsequent leaching circuit if the gold is not first removed.

GOLD FLOTATION The flotation process, which is today so extensively used for the concentration of basemetal sulphide ores and is finding increased use in many other fields. In 1932 flotation plants began to be installed for the treatment of gold and silver ores .

Froth flotation circuit design and basic testwork requirements Froth flotation is a very important mineral concentration process that is used to recover a vast array of different minerals containing valuable commodities such as copper, lead, zinc, nickel, molybdenum, tungsten, silver, gold, phosphate and potash.

WhatsApp)

WhatsApp)